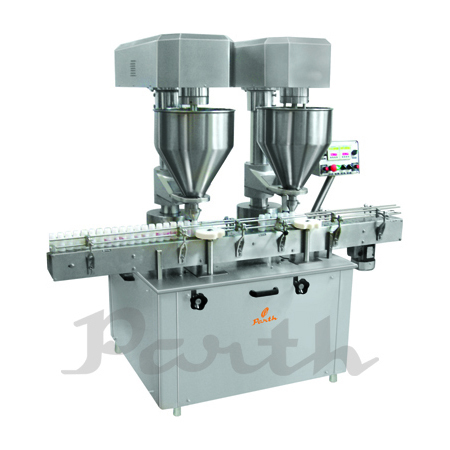

Double Head Auger Filling Machine

525000.0 INR/Unit

Product Details:

- Features Good Quality

- Usage & Applications Industrial

- Phase 3

- Temperature 22 Celsius (oC)

- Frequency 50 Hertz (HZ)

- Noise Level 80 db

- Type Auger Filler Machine

- Click to View more

X

Double Head Auger Filling Machine Price And Quantity

- 1 Unit

- 525000.0 INR/Unit

Double Head Auger Filling Machine Product Specifications

- No

- 200011001700 Millimeter (mm)

- 22 Celsius (oC)

- 3

- SS

- Industrial

- Good Quality

- 60 Pcs/min

- Silver

- Auger Filler Machine

- 500 Kilograms (kg)

- 80 db

- 1.75 Horsepower (HP)

- Automatic

- 50 Hertz (HZ)

- 220

- 1 year

Double Head Auger Filling Machine Trade Information

- ICD Khodiyar - Ahmedabad / Nava sheva

- Cheque, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 1 Unit Per Month

- 1 Months

- Yes

- Crate Packing, Base Packing, Export Worthy Wooden Packing

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- CE, ISO 9001 : 2015, D & B

Product Description

Our dedication and hard work towards the clients make us the most reliable manufacturer and exporter of Double Head Auger Filling Machine. This machine is highly demanded in the pharmaceutical industry to fill up dry syrup powder to the bottles in bulk. Our machine is produced at our advanced manufacturing unit by our experts using best quality materials in compliance with current industry standards. We have the facility to provide Double Head Auger Filling Machine at market leading prices.

Features:

- Excellent durability

- Non corrosive

- High performance

Precision and Efficiency Combined

The Double Head Auger Filling Machine offers remarkable precision and consistent filling, thanks to its automatic auger mechanism and robust construction. Its advanced engineering ensures minimal product wastage, improving productivity and cost-effectiveness in pharmaceutical and industrial packaging operations.

Durable Construction for Industrial Environments

Made entirely from stainless steel, this machine boasts a silver finish that is both visually appealing and corrosion-resistant. With a weight of 500 kg and sturdy dimensions (2000x1100x1700 mm), its designed to withstand rigorous use while maintaining hygiene standards in industrial settings.

FAQs of Double Head Auger Filling Machine:

Q: How does the Double Head Auger Filling Machine operate in an industrial setting?

A: The machine utilizes two auger heads for simultaneous filling, optimizing throughput for powders and similar products. Upon activation, product is dispensed precisely into containers at up to 60 pieces per minute, under fully automatic control, and minimal operator intervention is required.Q: What are the usage applications of this auger filler machine?

A: This auger filler is primarily used in pharmaceutical and other industrial environments for precise, high-speed filling of powder or granular products into various containers, ensuring clean and accurate packaging every cycle.Q: When should I perform maintenance on the Double Head Auger Filling Machine?

A: Routine maintenance is recommended based on daily operating hours and the nature of the product filled. Generally, regular cleaning and inspection should be performed every week or as advised by the manufacturer to ensure optimal functionality and hygiene.Q: Where can this machine be effectively utilized?

A: This machine is best suited for industrial settings such as pharmaceutical manufacturing units, chemical factories, and food processing plants across India, where bulk packaging of powder or granules is required.Q: What is the process for adjusting the fill weight on the machine?

A: Fill weight adjustment is managed via the automatic control system. Operators can set desired parameters on the control interface, ensuring each auger dispenses the exact required quantity per container.Q: How does the machine benefit my production line?

A: With its dual head design and automatic operation, the machine boosts throughput, reduces manual labor, minimizes spillage, and ensures consistent fill accuracy, helping streamline and modernize the packaging process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS