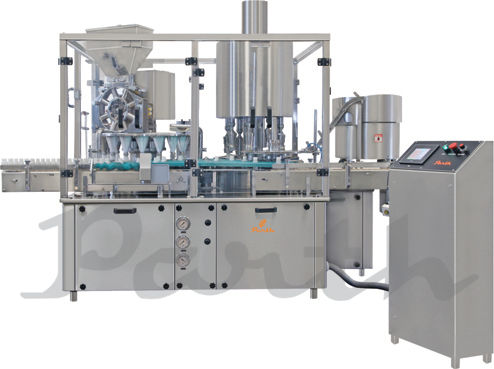

Automatic Rotary Dry Syrup Filling Sealing Machine

Product Details:

- Voltage 240 Volt (v)

- Driven Type Mechanical

- Accuracy 1 %

- Power 2.0 Horsepower (HP)

- Color Silver

- Application To pack powder in glass & hdpe bottle

- Weight 2500 Kilograms (kg)

- Click to View more

Automatic Rotary Dry Syrup Filling Sealing Machine Price And Quantity

- 1650000.0 INR/Unit

- 1 Unit

Automatic Rotary Dry Syrup Filling Sealing Machine Product Specifications

- Yes

- New

- Dry Syrup Filling Machine

- 120 Pcs/min

- 120 bpm

- Screw/ROPP

- 120 Pcs/min

- Mechanical

- 240 Volt (v)

- As per requirement

- Screw/ROPP

- 1250

- 2500 Kilograms (kg)

- To pack powder in glass & hdpe bottle

- Silver

- 2.0 Horsepower (HP)

- 1 %

Automatic Rotary Dry Syrup Filling Sealing Machine Trade Information

- ICD Khodiyar - Ahmedabad / Nava sheva

- Cheque, Telegraphic Transfer (T/T), Letter of Credit (L/C)

- 1 Unit Per Month

- 1 Months

- No

- Crate Packing, Base Packing, Export Worthy Wooden Packing

- North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia, Central America

- All India

- CE, ISO 9001 : 2015, D & B

Product Description

As an organization, we are trusted by our broad base of clients for manufacturing and exporting Automatic Rotary Dry Syrup Sealing Machine. This machine is manufactured t our advanced production unit by our professionals with high quality materials as per the industry set quality norms. Our machine is preferred in the pharmaceutical industry for sealing the dry syrup bottles appropriate to resist spillage. We offer Automatic Rotary Dry Syrup Sealing Machine to our valuable clients at a reasonable price.

Specification

|

Air Pressure |

6 bar pressure 0.5 CFM |

|

Bottle dia |

Min 25 to Max. 80mm |

|

Bottle Height |

Min 38mm to Max. 150mm |

|

Bottle Shape |

Round |

|

Bottle type |

Glass & HDPE |

|

Cap |

22mm, 25mm and 28mm |

|

Electrical load |

6.0 HP. 4.5 KW |

|

Electrical supply |

3 Phase + Neutral + Earthing |

Features:

- Robust structure

- Superb performance

- Less maintenance

Precise High-Speed Filling and Sealing

The automatic rotary dry syrup filling sealing machine is engineered for swift, precise operation, achieving up to 120 filled and sealed bottles per minute. Its advanced mechanical-driven technology ensures consistent powder dosing with an impressive 1% accuracy, making it ideal for pharmaceutical packaging where quality and compliance are paramount. With screw and ROPP sealing options, the system guarantees enhanced product protection and extended shelf life.

Versatile Application and Material Compatibility

Designed to accommodate a range of packaging requirements, this machine supports both glass and HDPE bottles, and adapts to various packaging materials as needed. Its flexible configuration makes it a reliable choice for manufacturers packaging different powdered formulations, particularly in the health, supplement, and pharmaceutical sectors. The automated operation and adaptability streamline production, reduce manual errors, and optimize workflow efficiency.

FAQs of Automatic Rotary Dry Syrup Filling Sealing Machine:

Q: How does the Automatic Rotary Dry Syrup Filling Sealing Machine ensure high accuracy in filling?

A: The machine utilizes mechanical-driven systems and precise volumetric dosing mechanisms that consistently achieve a filling accuracy of 1%. This minimizes waste and ensures that each glass or HDPE bottle contains the correct powder dosage.Q: What types of bottles and packaging materials can this machine handle?

A: This machine is suitable for both glass and HDPE bottles and is adaptable to various packaging materials as specified by production requirements, making it versatile for different dry syrup products.Q: When is an automatic rotary machine preferred over manual filling methods?

A: Automatic rotary machines are ideal when high production capacity (up to 120 bottles per minute) and consistent filling accuracy are required. They significantly reduce labor costs, minimize contamination risks, and enhance overall output quality.Q: Where is this dry syrup filling and sealing machine typically used?

A: It is predominantly used in pharmaceutical, nutraceutical, and food supplement manufacturing facilities, particularly for packaging dry powder formulations efficiently and safely.Q: What is the process followed by this machine from filling to sealing?

A: First, bottles are automatically positioned. The system then dispenses a precise amount of powder into each bottle, followed by automatic screwing or ROPP sealing, ensuring each container is securely closed and ready for downstream operations.Q: How does automation in this machine benefit manufacturers?

A: Automation boosts productivity by reducing manual intervention, increasing throughput, enhancing consistency, and lowering the risk of human error. It also helps in maintaining hygiene standards crucial for pharmaceutical products.Q: What are the key benefits of using this rotary filling and sealing machine for exporters and suppliers in India?

A: The machines robust build, compliance with industry standards, and high-speed output make it an excellent investment for exporters and suppliers aiming to cater to both domestic and international markets with reliable and efficient packaging solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS